What Industry 4.0 Means for Retail, and What Two Areas You Should Invest in First

There are certain elements we expect to see in a science fiction story. Futuristic concepts. Interplanetary conflict, sometimes featuring aliens. Currency that’s measured in credits . Superintelligent robots. Artificial intelligence. Self-monitoring machines.

With the exception of the aliens — as far as we know — much of what was once relegated to the realm of sci-fi can be found in how modern-day business works.

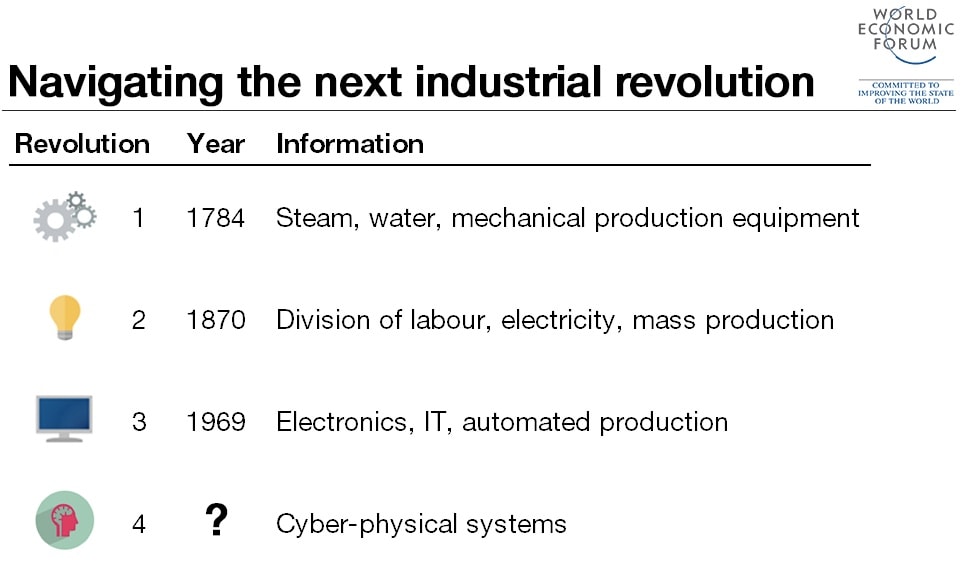

It’s called Industry 4.0, or the fourth industrial revolution. Like past industrial revolutions, which we’ll cover in a bit, this one is characterized by a major shift in how things are made, bought, delivered, and experienced. Technologies like AI, advanced robotics, and the internet of things (IoT) are ushering us into an experience that’s not limited to the page or the screen. Industry 4.0 is real, it’s built on interconnectivity and automation, and it’s changing the way the world works.

What does Industry 4.0 mean for ecommerce businesses and how can retailers make the most of the opportunities Industry 4.0 presents? That’s what we’ll explore here.

But first, some history.

The First Industrial Revolution

It’s 1710 in Britain. The clothes on your back — and everyone else’s — are probably homespun, made from textiles that came from small local workshops and had been made by hand.

Fast forward 100 years later, and that’s no longer the case. Big steam- and water-powered factories are weaving cloth on power looms. Making fabric no longer requires hours and hours of painstaking human labor.

The First Industrial Revolution , usually marked between 1760-1840, marked a shift from hand production to machinated productions. Its impact in the textile industry was profound, but it also impacted agriculture and mining in both the United States and Europe.

The Second Industrial Revolution

We left you in 1810 with your factory-produced clothing. But if you zoom forward another 100 years, it’s not just your clothes that will change. A whole new set of mass-produced goods are available to you, from sewing machines to soap. And while electricity changed how those goods were made, the railroad transformed how they got around.

The Second Industrial Revolution is usually dated from 1870 to 1914, and is characterized by its reliance on technology and invention to build industries at scale. From Ford to Carnegie Steel, companies built systems like the assembly line and cross-country railroads to mass-produce their goods. In turn, the shift from farm labor to factory labor created the middle class (and the labor movement) and gave workers not just new income but new things to spend it on.

The Third Industrial Revolution, or the Digital Revolution

The way that goods were produced, moved, and consumed changed greatly from 1710 to 1910 during the first two industrial revolutions. But it was still mostly physical changes: new materials and mechanisms meant cheaper goods that were more quickly produced and shipped.

The Third Industrial Revolution , also called the Digital Revolution, transformed industry by translating it. Instead of conceiving of production as something driven by people or machines, it became something driven and enabled by computers. Physical goods were still produced, of course — but they were managed, advertised, and sold with information technology that expanded commerce (global marketplaces!) while also shrinking it small enough to fit in our pockets.

The Digital Revolution started in the 1950s, when companies like Bell Labs were inventing early technology that led to the first computers. The internet was invented in 1969; the personal computer in the 1970s; the mobile phone in the 1990s. More and more work transitioned from humans to computers.

The Fourth Industrial Revolution, or Industry 4.0

The World Economic Forum introduced the idea of Industry 4.0 — the Fourth Industrial Revolution — in a paper it published in 2016 . Its central argument is this:

The world is at the beginning of a new industrial revolution that builds on the digital one that came before by combining the physical, digital, and biological worlds and transforming the way work is done.

And those transformations will create new seats of power. In 2020, author, advisor, and Brookings expert Rush Doshi testified before the U.S. Senate about the importance of the Fourth Industrial Revolution and the potential for China, long a rival on the stage for global power, to surpass the U.S. in actualizing its vision. He noted that China’s vision for Industry 4.0 is built on:

Artificial intelligence

Big data

Quantum information

Biotechnology

What does Industry 4.0 look like for retail?

Scenes from Industry 4.0 include:

Little blue driverless trucks, Seegrid’s autonomous mobile robots (AMRs) , bringing work-in-progress goods from one part of the assembly line to another, dropping off pallets of goods without human interference.

A transportation company tracking their trucks with Emitu’s Industrial Internet of Things (IIoT) asset-tracking software, giving them a real-time view on food storage temperature, delivery times, humidity, and other key factors — so they can more quickly adjust if something goes wrong and can also provide more real-time transparency to their clients.

An engineer walking around a factory floor, seeing a hazard, and instead of waiting three hours until she’s back at her desk to file an incident report, using an AI-enabled mobile app like Datch to speak conversationally into her cell phone and report it. (After which the app automatically sends a report to the maintenance team, who dispatches someone to fix the problem.)

A supply chain manager using Anvyl’s machine-learning software to analyze the delay of risks to orders and proactively get in sync with suppliers about issues, leveraging a digital library of past orders and parts.

A livestock farmer using IIoT-connected software Farmcloud to measure conditions at their production houses remotely so they can thoughtfully cut energy usage and reduce water consumption and waste.

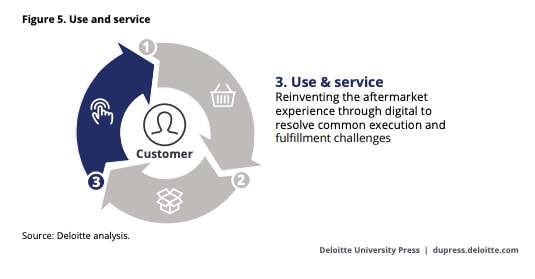

Industry 4.0 is transforming how goods are made, it’s true. But according to Deloitte, the most powerful part of this revolution doesn’t happen on the factory floor.

Instead, the power of Industry 4.0 is in customer expectations: how companies manage, meet, and exceed them after purchase.

Why customer experience is the most important investment in Industry 4.0 you can make

Deloitte, in a report on how Industry 4.0 engages customers , calls it the most impactful part of Industry 4.0 the “aftermarket experience,” or what happens after an original sale occurs. It’s “most significant area in which manufacturers can realize value from Industry 4.0.”

It makes sense. With more data, transparency, and efficiency on the production side, retailers know where their products are, how exactly they’re being made, when they’re being sent, and when they’ll arrive. Similar things are happening on the post-purchase side, and there are opportunities to transform the customer experience — and drive significant growth — by leveraging them.

That report notes that “about 50% of S&P 500 firms will likely be replaced over the next 10 years due to new digital disrupters and inability of established firms to reinvent themselves.”

To be in the half that makes it through — that leans into the power of Industry 4.0 and uses it to transform not just work but also the way that you relate to your customers — you need to consider customer expectations and customer communication.

Focus area 1: Rising to the level of increased customer expectations

Deloitte found that customers’ satisfaction levels for aftermarket services are 10-15% below their expectations.

The physical / digital divide no longer exists. Customers don’t forget about you as soon as their purchase arrives. They’re staying connected through digital marketing, online customer service, and future ecommerce purchases. They want you to meet them there, whether that’s by servicing products that break, providing ongoing education on product usage, or fixing problems as they come up.

You can meet those expectations by investing ownership enrichment , or on improving the experience of being a product owner.

Clyde’s Extended Warranty offerings cover your customers in the case that the unexpected happens and their product breaks.

And our Resolution tool centralizes, automates, and successfully resolves issues with your products in one place. It draws in data from every sales channel and automatically integrates it with your service tools, using it to resolve customer issues — and support team headaches — faster.

Focus area 2: Owning customer data and using it to build relationships

In introducing Industry 4.0, the World Economic Forum highlighted the importance of giving customers the information they’re looking for.

“Whether consumers or businesses, customers are increasingly at the epicenter of the economy, which is all about improving how customers are served,” wrote WE Forum founder Klaus Schwab, adding ways that improvement is happening:

Giving physical products and services digital capabilities that make them more valuable

Utilizing data and analytics to better maintain and service products

Consumer expectations for personalization and transparency are rising:

64% of shoppers will switch brands for more in-depth product transparency, found Nielsen

And 71% of consumers want more personalized interactions from companies, per McKinsey

It’s more important than ever to know who your customers are and have a plan for communicating with them in all channels, at all stages of the purchase process. That’s everything from clear product sourcing information and useful transactional emails keeping them updated on shipping timelines and extended warranty options.

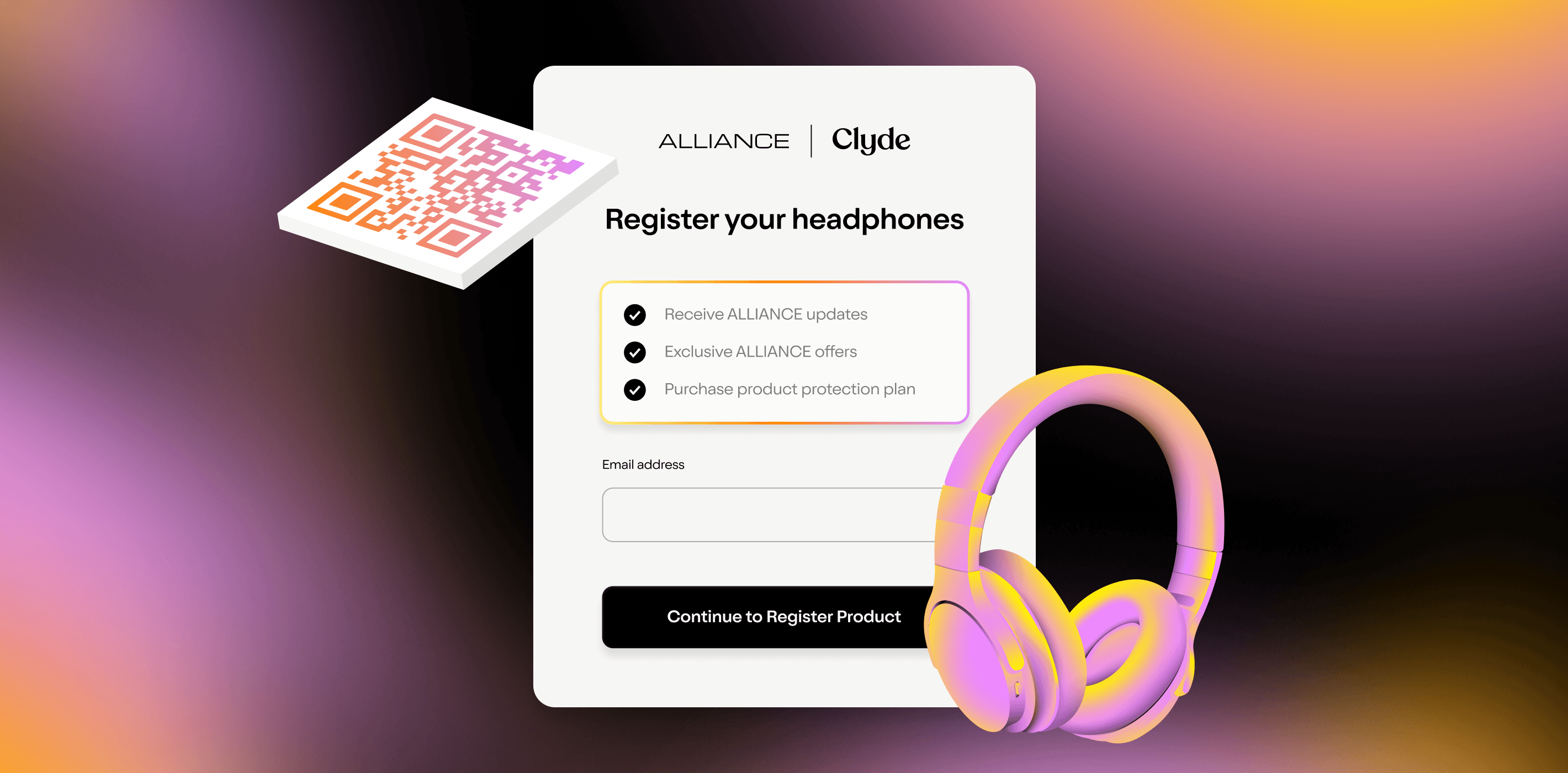

To do that, you need first-party data — and a way to get it when customers purchase your products from a third party.

Clyde’s registration tool leads customers back to you by having them register their product once it arrives, even if the sale didn’t happen through you directly.

Industry 4.0-enabled production lines let you respond to real-life needs, tastes, and changes with unprecedented customization. Your post-purchase service and communication model should use the same technologies, including AI and big data, to do the same thing.

In conclusion

The Fourth Industrial Revolution is all about connected manufacturing and service. Products aren’t made — or used — in isolation. Knowing more about how both sides of those ecosystems work allow companies to make better products and meet growing customer expectations. And engaging in transparent, personalized communication along the way allows the buyer-seller relationship to flourish over time.

Extend the power of Industry 4.0 through the entire lifecycle of your product by partnering with Clyde to transform the post-purchase journey. Sign up for a free product walkthrough today .

SIGN UP FOR OUR NEWSLETTER